Businesses and consumers are increasingly seeking, even demanding, safer and nontoxic products. Forward-thinking entrepreneurial firms now incorporate sustainable design considerations to provide preferred design and product formulations. This chapter provides examples of companies that have adopted sustainability strategies and as a consequence designed better, healthier, and cleaner products. In these case examples we see companies applying systems and molecular thinking approaches, green chemistry concepts, cradle-to-cradle design ideas, and green supply-chain practices to meet the growing demand for “clean” products.

We introduce this chapter with a background discussion on green supply chains. This background material applies to all the cases, not just those in this chapter. It is important to understand that an individual company’s “clean” and “green” operations and strategy may be real and laudable, but sustainability is a systems concept that, at minimum, applies to the network of suppliers and buyers composing the value chain. Students should be sure to apply the green supply chain background information to all the cases discussed.

Regardless of how you might feel about Walmart, the effect of the company’s sustainability policies are being felt worldwide through its supply chains. On February 1, 2007, Walmart President and CEO Lee Scott announced his company’s “Sustainability 360” program would expand Walmart’s sustainability efforts from its operations and into its supply chains by “tak[ing] in,” as Scott said, “our entire company—our customer base, our supplier base, our associates, the products on our shelves, the communities we serve.”Walmart, “Wal-Mart CEO Lee Scott Unveils ‘Sustainability 360,’” news release, February 1, 2007, accessed January 10, 2011, http://walmartstores.com/pressroom/news/6237.aspx. Walmart customers could now track the company’s “Love, Earth” jewelry all the way back to the mine or buy fish certified by the Marine Stewardship Council. In 2010 the company announced the goal of a twenty-million-metric-ton greenhouse gas emission reduction from its global supply chain (encompassing over one hundred thousand suppliers).Walmart, “Sustainability Fact Sheet: Wal-Mart Takes the Lead on Environmental Sustainability,” news release, March 1, 2010, accessed January 30, 2011, http://walmartstores.com/download/2392.pdf. Furthermore, Walmart enlisted the nonprofit Carbon Disclosure Project, institutional investors with $41 trillion in assets as of September 2007, to help Walmart’s suppliers of DVDs, toothpaste, soap, milk, beer, vacuum cleaners, and soda to assess and reduce their carbon footprints.Ylan Q. Mui, “Wal-Mart Aims to Enlist Suppliers in Green Mission,” Washington Post, September 25, 2007, accessed January 10, 2011, http://www.washingtonpost.com/wp-dyn/content/article/2007/09/24/AR2007092401435.html. Indeed, with roughly one hundred thousand suppliers, two million employees, and millions of customers per day,Walmart, “Sustainability Fact Sheet: Wal-Mart Takes the Lead on Environmental Sustainability,” news release, March 1, 2010, accessed January 30, 2011, http://walmartstores.com/download/2392.pdf. Walmart’s operations and those it encouraged, from product design and resource extraction through final consumption and disposal, could massively influence societies and the natural environment. As such impacts attracted attention, so did the benefits of and the need for greener supply networks.

Green supply chains (GSCs)Approaches to sourcing and production that consider sustainability for every participant at every step, from design to manufacture, transportation, storage, and use to eventual disposal or recycling. became Supply Chain Digest’s number one supply-chain trend of 2006 as more companies such as Walmart embraced them.Dan Gilmore, “Top Ten Supply Chain Trends of 2006,” Supply Chain Digest, January 4, 2006, accessed January 10, 2011, http://www.scdigest.com/assets/FirstThoughts/07-01-04.cfm?cid=871&ctype=content. Fully developed green supply chains consider sustainability for every participant at every step, from design to manufacture, transportation, storage, and use to eventual disposal or recycling. This attentiveness would reduce waste, mitigate legal and environmental risks, minimize and possibly eliminate adverse health impacts throughout the value-added process, improve the reputations of companies and their products (enhancing brands), and enable compliance with increasingly stringent regulations and societal expectations. Thus GSCs offer the opportunity to boost efficiency, value, and access to markets through improving a company’s environmental, social, and economic performance.

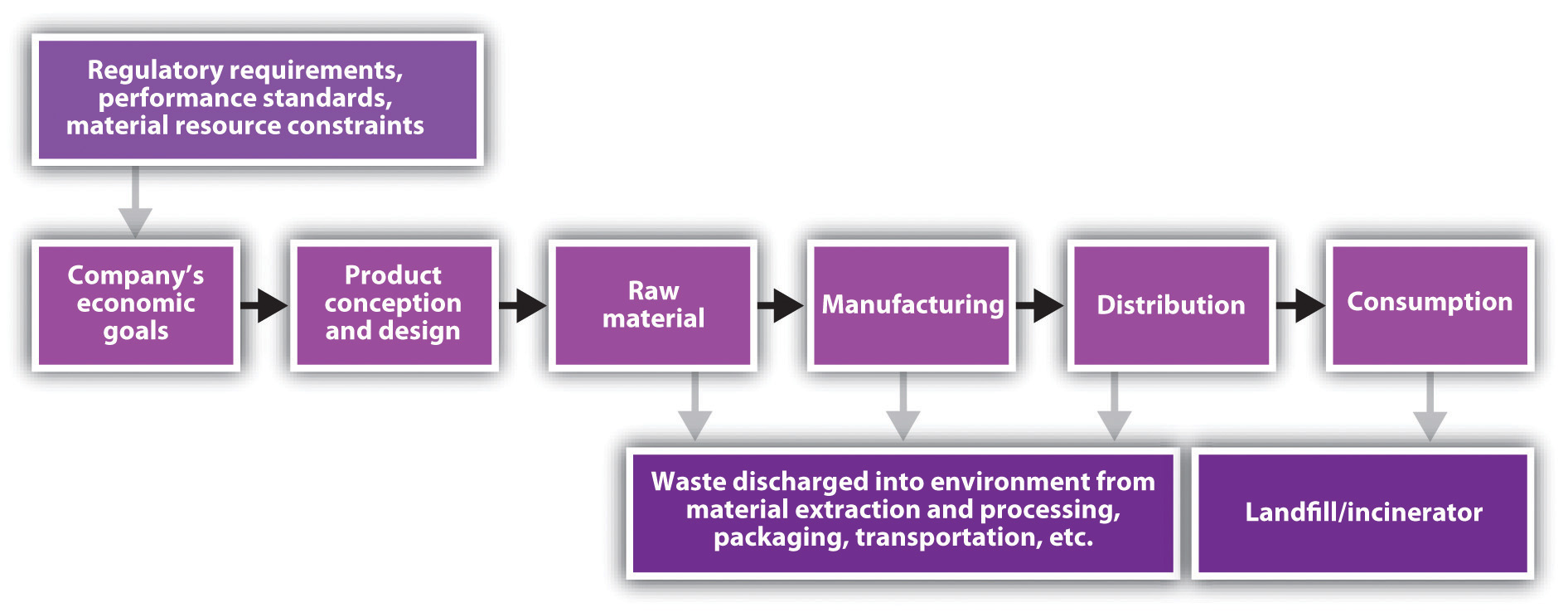

Figure 6.1 The Conventional Supply Chain

In its simplest form, a conventional supply chain assumes that firms take raw materials at the beginning of the supply chain and transform them into a product at the end of the supply chain. Ultimately, the supply chain terminates at the point of the final buyer purchasing and using the product (see Figure 6.1 "The Conventional Supply Chain"). Vertical integration absorbs steps in the supply chain within a single corporation that conducts exchange through internal transfer pricing agreements. Disaggregation maintains ownership in discrete businesses that determine prices through market-based transactions.

A company that sells a final product must meet certain requirements and interact with suppliers, third-party logistics providers, and other stakeholder groups that can influence the entire process. Each institution tries to shape the supply chain to its own advantage. As the product moves from design to consumption (black arrows), waste and other problems (gray arrows) accrue. Whether those problems are unfair wages, deforestation, or air pollution, these costs are not necessarily reflected in the price of the finished product but are instead externalized to the public in some fashion or expected to be borne by intermediate links in the conventional chain.

While the term supply chain implies a one-way, linear relationship among participants (e.g., from concept, to resource extraction, to processing, to component manufacturing, to system integration, to final assembly, etc.), the chain is more accurately described as a network of individuals and organizations. Managing such networks can become quite complex, especially as they sprawl over more of the globe. Conventional supply-chain management plans, implements, and controls the operations of the supply chain as efficiently as possible—typically, however, from a limited vantage point that ignores and externalizes many costs.

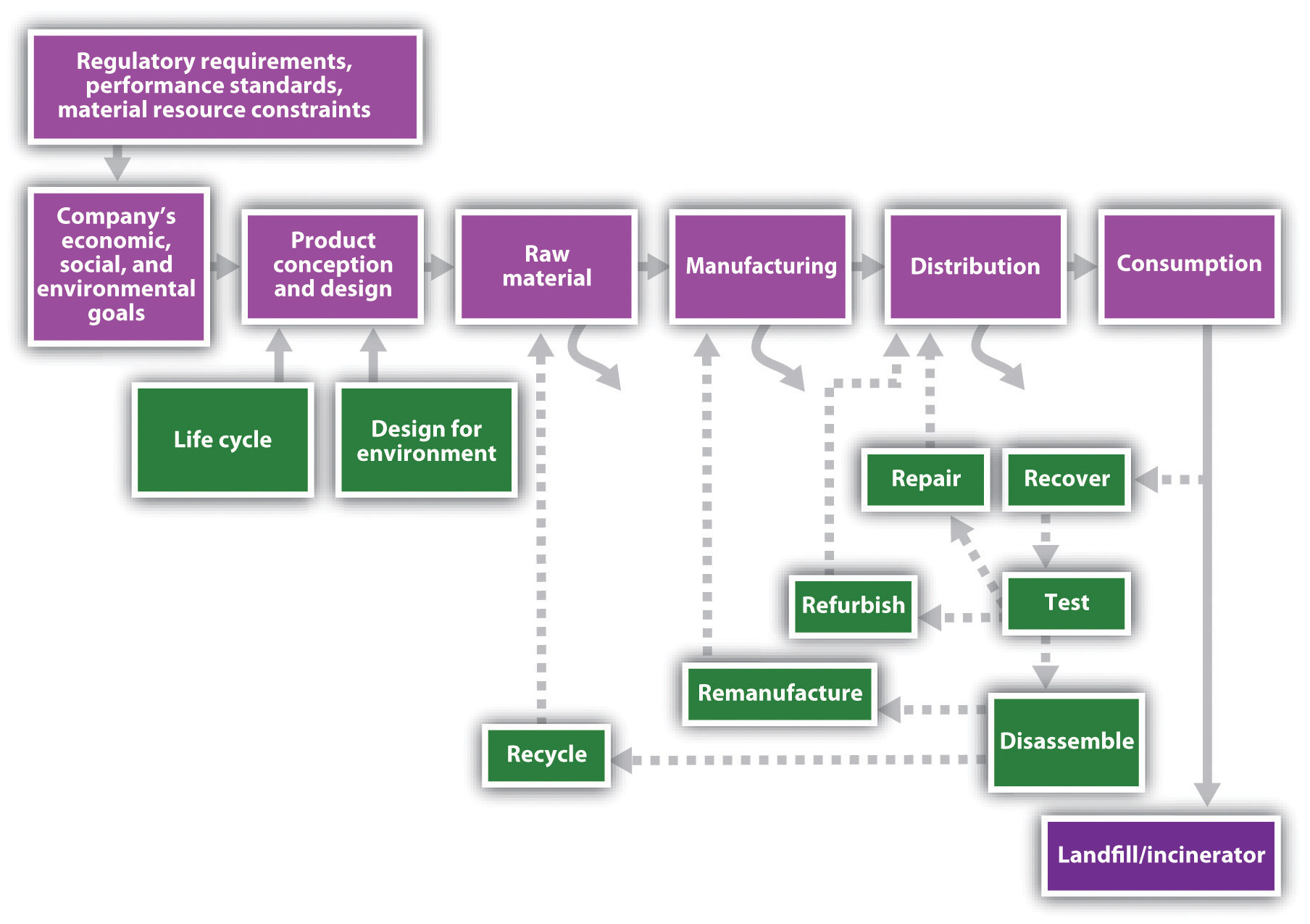

In contrast, a green supply chain takes a broader, systems view that internalizes some of these costs and ultimately turns them into sources of value. Green supply chains thus modify conventional supply chains in two significant ways: they increase sustainability and efficiency in the existing forward supply chain and add an entirely new reverse supply chain (see Figure 6.2 "The Green Supply Chain").

Figure 6.2 The Green Supply Chain

A company can select various ways to improve the sustainability of its logistics systems. The company may communicate sustainability standards backward to suppliers and require them to adopt environmental management systems or certifications, such as ISO 14001; survey and monitor suppliers’ current practices or products for their sustainability and offer training, technology, and incentives to improve those practices or products;According to the International Organization for Standardization, which established this qualification, ISO 14001 “gives the requirements for quality management systems [and] is now firmly established as the globally implemented standard for providing assurance about the ability to satisfy quality requirements and to enhance customer satisfaction in supplier–customer relationships.” International Organization for Standardization, “ISO 14001:2004,” accessed January 10, 2011, http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=31807. require suppliers to avoid certain hazardous ingredients and label others; and/or ask suppliers and other supporting firms, such as transportation companies, to suggest ways to improve the efficiency and sustainability of the whole process. Hence companies “greening” their supply chains are likely to communicate and collaborate more with suppliers and subcontractors to innovate and find the best solutions. They might also reach out to nongovernmental organizations (NGOs) and government agencies for further assistance.

For example, US-based DesignTex, in the 1990s a leader in the contract textile industry and now a subsidiary of US commercial furniture manufacturer Steelcase,DesignTex, “Designtex, A Steelcase Company: Our Company,” accessed January 30, 2011, http://store.designtex.com/ourcompany.aspx?f=35398. chose to pursue an environmentally friendly commercial upholstery fabric. DesignTex collaborated with a small Swiss firm called Rohner Textil AG, chemical corporation Ciba Geigy, and the Environmental Protection Encouragement Agency (a German NGO) to determine product specifications, develop fabric requirements, and identify substitute benign chemicals for the toxic chemicals present along the fabric supply chain.Matthew M. Mehalik, “Sustainable Network Design: A Commercial Fabric Case Study,” Interfaces: International Journal of the Institute for Operations Research and the Management Sciences 30, no. 3 (May/June 2000): 180–89. The new product’s supply chain originated from the wool of free-range sheep and ramie grown without pesticides to a yarn-twisting mill and dye manufacturers, with scraps of the textile generated along the way being sold to farmers and gardeners for mulch.

Surprisingly, the production changes did not just reduce DesignTex’s environmental impact; they also added value: The factory’s effluent became cleaner than the incoming water supply. Regulatory paperwork was eliminated. Workers no longer needed protective masks or gloves, which eliminated health risks and liability exposure.William McDonough and Michael Braungart, “Waste Equals Food,” in Cradle to Cradle: Remaking the Way We Make Things (New York: North Point Press, 2002). Because of these decreased costs and the tax relief for the accompanying environmental investments, the innovation showed a payback period of only five years.Matthew M. Mehalik, “Sustainable Network Design: A Commercial Fabric Case Study,” Interfaces: International Journal of the Institute for Operations Research and the Management Sciences 30, no. 3 (May/June 2000): 180–89. It also was an early, successful illustration of cradle-to-cradle design, the cyclical design protocol that allows biologically benign products to safely return to nature.

In addition to dramatically improving conventional supply-chain logistics, green supply chains extend past the point of product use, where conventional chains end, and consider how to recover and reuse materials—questions of reverse logisticsThe part of the supply chain that takes used products from consumers and recycles, refurbishes, or otherwise disposes of those products.. Many companies already have rudimentary reverse logistics systems to deal with customers’ returns of items they do not want or that were found defective or otherwise unsatisfactory. An expanded reverse logistics system would ultimately replace the linearity of most production methods—raw materials, to processing, to further conversions and modification, to ultimate product, to use, to disposal—with a cradle-to-cradle, cyclical path or closed loop that begins with the return of used, outmoded, out-of-fashion, and otherwise “consumed” products. The products are either recycled and placed back into the manufacturing stream or broken down into compostable materials. The cycle is never ending because materials return to the land in safe molecular structures (taken up and used by organisms as biological nutrients) or are perpetually used within the economy as input for new products (technical nutrients).

Companies typically funnel spent items from consumers into the reverse supply chain by leasing their products or providing collection points or by other means of recovering the items once their service life ends.Shad Dowlatshahi, “Developing a Theory of Reverse Logistics,” Interfaces: International Journal of the Institute for Operations Research and the Management Sciences 30, no. 3 (May/June 2000): 143–55. For example, Canon and Xerox provide free shipping to return used toner cartridges and have thus collectively recovered over one hundred thousand tons of ink and cartridges since 1990.Canon, “Toner Cartridge Return Program,” accessed October 2, 2009, http://www.usa.canon.com/templatedata/AboutCanon/ciwencrpr.html; Xerox, “Prevent and Manage Waste,” accessed January 10, 2011, http://www.xerox.com/about-xerox/recycling/supplies/enus.html.

Once collected, whether by the original manufacturer or a third party, the products could be inspected and sorted. Some items might return quickly to the supply chain with only minimal repair or replacement of certain components, whereas other products might need to be disassembled, remanufactured, or cannibalized for salvageable parts while the remnant is recycled or sent to a landfill or incinerator. “Companies that remanufacture are estimated to save 40–60 percent of the cost of manufacturing a completely new product…while requiring only 20 percent of the effort,” leading to significant, structural savings, wrote Shad Dowlatshahi in Interfaces.Shad Dowlatshahi, “Developing a Theory of Reverse Logistics,” Interfaces: International Journal of the Institute for Operations Research and the Management Sciences 30, no. 3 (May/June 2000): 144. Moreover, the reverse supply chain might spawn new suppliers as well as other sources of revenue for companies that engage in collection, disassembly, and so on, making the entire network more efficient.Joy M. Field and Robert P. Sroufe, “The Use of Recycled Materials in Manufacturing: Implications for Supply Chain Management and Operations Strategy,” International Journal of Production Research 45, no. 18–19 (October 2007): 4439–63. This concept of an eco-efficient closed loop thereby makes green supply chains a central piece of sustainable industrial ecosystems.

The same techniques that improve the sustainability of conventional logistics also aid reverse logistics. In addition, green supply chains fundamentally require two tools: life-cycle assessment (LCA) and design for environment (DfE). According to the US Environmental Protection Agency’s National Risk Management Research Laboratory, LCA takes the viewpoint of a product, process, or service by “(1) compiling an inventory of relevant energy and material inputs and environmental releases; (2) evaluating the potential environmental impacts associated with identified inputs and releases; [and] (3) interpreting the results to help you make an informed decision,” typically to minimize negative impacts across the entire life of the product.US Environmental Protection Agency, “Life-Cycle Assessment (LCA),” accessed January 10, 2011, http://www.epa.gov/ORD/NRMRL/lcaccess. For examples, see Maurizio Bevilacqua, Filippo Emanuele Ciarapica, and Giancarlo Giacchetta, “Development of a Sustainable Product Lifecycle in Manufacturing Firms: A Case Study,” International Journal of Production Research 45, no. 18–19 (2007): 4073–98, as well as Stelvia Matos and Jeremy Hall, “Integrating Sustainable Development in the Supply Chain: The Case of Life Cycle Assessment in Oil and Gas and Agricultural Biotechnology,” Journal of Operations Management 25, no. 6 (2007): 1083–82. This analysis helps identify the points in the green supply chain that detract from ultimate sustainability and establishes a baseline for improvement. For example, Walmart’s third-party logistics provider in Canada began using railways more than roads to supply ten stores, thereby cutting carbon emissions by 2,600 tons. The company estimated it would save another $4.5 million and prevent 1,400 tons of waste annually by switching from cardboard to plastic shipping crates.“Wal-Mart’s ‘Green’ Campaign Pays Off in Canada,” DC Velocity, October 1, 2007, accessed October 2, 2009, http://www.dcvelocity.com/news/?article_id=1338.

Application of DfE acknowledges that design determines a product’s materials and the processes by which the product is made, shipped, used, and recovered. Hence DfE could be used to avoid toxic materials from the outset; minimize energy and material inputs; and facilitate disassembly, repair, and remanufacturing. For instance, Hewlett Packard (HP) used DfE “product stewards,” whose role, HP explained, was as follows: “[Product stewards] are integrated into product design and research and development teams to identify, prioritize, and recommend environmental design innovations to make products easier to disassemble and recycle. Such features include modular designs, snap-in features that eliminate the need for glues and adhesives, fewer materials, and molded-in colors and finishes instead of paint, coatings, or plating.”Hewlett-Packard, “HP to Eliminate Brominated Flame Retardants from External Case Parts of All New HP Brand Products,” news release, November 1, 2005, accessed January 11, 2011, http://www.hp.com/hpinfo/newsroom/press/2005/051101a.html.

Conversely, process designs could influence product designs through new technology that implements an innovative idea. For example, in the Walden Paddlers case discussed in Section 4.5 "Adaptive Collaboration through Value-Added Networks", Hardigg Industries was a plastics-molding company that partnered with Clearvue Plastics to create plastic pellets with 50 percent recycled content, which Hardigg thought was impossible until it was encouraged by the entrepreneurial founder of Walden Paddlers. Later, Hardigg was able to change its rotomolding technology to allow for the use of 100 percent recycled resins. Through the use of recycled materials and Clearvue’s innovation, Hardigg was able to lower costs, establish a competitive advantage within its industry, attract new customers, and increase customer satisfaction.Paul H. Farrow, Richard R. Johnson, and Andrea L. Larson, “Entrepreneurship, Innovation, and Sustainability Strategies at Walden Paddlers, Inc.,” Interfaces: International Journal of the Institute for Operations Research and the Management Sciences 30, no. 3 (May/June 2000): 215–25.

Although green supply chains could present novel challenges, they had spread to address a convergence of legal requirements, consumer expectations, and competition for continued profitability. In 2001, a study of twenty-five suppliers showed 80 percent received significant requests to improve the environmental quality of their operations and products, and they in turn asked their suppliers to do the same.Business for Social Responsibility Education Fund, Suppliers’ Perspectives on Greening the Supply Chain (San Francisco: Business for Social Responsibility Education Fund, 2001), accessed January 11, 2011, http://www.getf.org/file/toolmanager/O16F15429.pdf. A larger survey from 2008 indicated 82 percent of respondents were planning to implement or were already implementing green supply-chain management strategies.Walfried M. Lassar and Adrian Gonzalez, The State of Green Supply Chain Management: Survey Results (Miami, FL: Ryder Center for Supply Chain Management, Florida International University, 2008), accessed January 11, 2011, http://grci.calpoly.edu/projects/sustaincommworld/pdfs/WP_Florida_Supply_Chain_Mgmt.pdf. The trend toward green supply chains was expected to continue.

Concern for green supply-chain topics emerged in the 1990s as, on one hand, globalization and outsourcing made supply networks increasingly complex and diverse and, on the other hand, new laws and consumer expectations increasingly demanded that companies take more responsibility for their products across the entire life of those products.Jonathan D. Linton, Robert Klassen, and Vaidyanathan Jayaraman, “Sustainable Supply Chains: An Introduction,” Journal of Operations Management 25, no. 6 (November 2007): 1075–82; Going Green Upstream: The Promise of Supplier Environmental Management (Washington, DC: National Environmental Education and Training Foundation, 2001), accessed January 11, 2011, http://www.neefusa.org/pdf/SupplyChainStudy.pdf. Companies had to more closely monitor their suppliers. Total quality management and conventional supply-chain management adapted to address some of these challenges in “a paradigm shift [that] occurred when the scope of analysis was broadened beyond what was customary [for operations analysts] at the time.”Charles J. Corbett and Robert D. Klassen, “Expanding the Horizons: Environmental Excellence as Key to Improving Operations,” Manufacturing and Service Operations Management 8, no. 1 (Winter 2006): 5–22. These broader management practices and ISO 9001 in turn laid the foundation for green supply-chain management and ISO 14001.

Between 2000 and 2009, the increased emphasis on sustainability expanded the scope further and deeper into environmental, public health, and community/social issues and embraced stakeholders beyond consumers and investors.Charles J. Corbett and Robert D. Klassen, “Expanding the Horizons: Environmental Excellence as Key to Improving Operations,” Manufacturing and Service Operations Management 8, no. 1 (Winter 2006): 5–22. This new paradigm of “extended producer responsibility,” which included a call for greater transparency and accountability, also compelled companies toward green supply-chain design.Markus Klausner and Chris T. Hendrickson, “Reverse-Logistics Strategy for Product Take-Back,” Interfaces: International Journal of the Institute for Operations Research and the Management Sciences 30, no. 3 (May/June 2000): 156–65.

Laws to reduce human exposure to hazardous and toxic chemicals drive corporate attention to supply-chain materials use. Noncompliance with laws could hurt profits, market share, and brand image. For example, Dutch customs agents prevented approximately $160 million worth of Sony PlayStation consoles from entering Holland in December 2001 because cadmium levels in their wiring exceeded levels set by Dutch law.Adam Aston, Andy Reinhardt, and Rachel Tiplady, “Europe’s Push for Less-Toxic Tech,” BusinessWeek, August 9, 2005, accessed January 11, 2011, http://www.businessweek.com/technology/content/aug2005/tc2005089_9729 _tc_215.htm. Sony disputed the root cause with its Taiwanese cable supplier but nonetheless had to pay to store, refurbish, and repack the machines.

Most forward-thinking global firms moved toward adopting consistent standards across all their markets, as opposed to different standards for different countries. Hence the tightest rules from one place tended to become the de facto global standard. For example, the EU’s directives 2002/95/EC on “the Restriction of the Use of certain Hazardous Substances in Electrical and Electronic Equipment” (RoHS) and 2002/96/EC on “Waste Electrical and Electronic Equipment” (WEEE) had many ramifications for suppliers and producers in the electronics industry. RoHS required all manufacturers of electronics and electrical equipment sold in Europe by July 2006 to substitute safer materials for six hazardous substances, such as lead and chromium. WEEE required producers to collect their electronic waste from consumers free of charge.European Commission, “Environment: Waste Electrical and Electronic Equipment,” accessed January 11, 2011, http://ec.europa.eu/environment/waste/weee/index_en.htm. The EU’s 2006 directive on “Registration, Evaluation, Authorization, and Restriction of Chemicals” (REACH) might further tighten global standards for producers and suppliers because it “gives greater responsibility to industry to manage the risks from chemicals and to provide safety information on the substances.”European Commission, “Environment: REACH,” accessed January 11, 2011, http://ec.europa.eu/environment/chemicals/reach/reach_intro.htm. Similar efforts have begun in Asia with Japan’s Green Procurement rules and China’s Agenda 21 goals.Adam Aston, Andy Reinhardt, and Rachel Tiplady, “Europe’s Push for Less-Toxic Tech,” BusinessWeek, August 9, 2005, accessed January 11, 2011, http://www.businessweek.com/technology/content/aug2005/tc2005089_9729 _tc_215.htm.

Consumers and institutional investors, meanwhile, have exerted pressure on companies through a variety of tactics from socially responsible investment screening criteria to market campaigns for engaging in fair trade or ending sweatshop labor. Failure to publicly improve practices anywhere along the supply chain could hurt brand image and curtail access to markets. American universities and colleges founded the Worker Rights Consortium in 2000 “to assist universities with the enforcement of their labor rights codes of conduct, which were adopted to protect the rights of workers producing apparel and other goods bearing university names and logos.”Worker Rights Consortium, “Mission: History,” accessed October 2, 2009, http://www.workersrights.org/about/history.asp. Manufacturers such as Canada’s Hudson Bay Company began to audit suppliers’ factories for compliance with labor standards.Tim Reeve and Jasper Steinhausen, “Sustainable Suppliers, Sustainable Markets,” CMA Management 81, no. 2 (April 2007): 30–33. By 2005, the Investor Environmental Health Network, following the effective strategy of institutional investors negotiating with companies for more action and accountability on climate change, was encouraging investment managers and corporations to reduce high-risk toxic chemicals used in their products and used by companies in which they invest.

Businesses might face novel challenges when implementing, operating, or auditing green supply chains. Given these challenges, businesses that already used an environmental management system were more equipped to build a green supply chain.Nicole Darnall, G. Jason Jolley, and Robert Handfield, “Environmental Management Systems and Green Supply Chain Management: Compliments for Sustainability?” Business Strategy and the Environment 17, no. 1 (2008): 30–45; Toshi H. Arimura, Nicole Darnall, and Hajime Katayama, Is ISO-14001 a Gateway to More Advanced Voluntary Action? A Case for Green Supply Chain Management, RFF DP 09-05 (Washington, DC: Resources for the Future, 2009), accessed January 11, 2011, http://www.rff.org/documents/rff-dp-09-05.pdf. Nonetheless, all businesses could take steps to green their chains.

“Green” has become strategic. When sustainability is recognized as an operating and strategic opportunity, as in the cases of General Electric and Walmart, senior management supports green supply-chain initiatives and integrates them into the business’s core capabilities.Terry F. Yosie, Greening the Supply Chain in Emerging Markets: Some Lessons from the Field (Oakland, CA: GreenBiz, 2008), accessed January 11, 2011, http://www.greenbiz.com/sites/default/files/document/GreenBiz_Report_Greening _the_Supply_Chain.pdf; Samir K. Srivastava, “Green Supply-Chain Management: A State-of-the-Art Literature Review,” International Journal of Management Reviews 9, no. 1 (March 2007): 53–80. In 2010, however, authority over green supply chains still tended to be held by a variety of groups, such as supply-chain managers, environmental health and safety offices, and sustainability divisions.Walfried M. Lassar and Adrian Gonzalez, The State of Green Supply Chain Management: Survey Results (Miami, FL: Ryder Center for Supply Chain Management, Florida International University, 2008), accessed January 11, 2011, http://grci.calpoly.edu/projects/sustaincommworld/pdfs/WP_Florida_Supply_Chain_Mgmt.pdf. Personnel who might have once functioned separately within a company often had to collaborate and create new teams for green supply chains to work effectively, and those people needed time for the green supply chains to yield their maximum benefits.

Companies must actively include suppliers and service providers in greening supply chains so that they can build trust, lend their own expertise to increase sustainability, and receive adequate guidance and assistance in improving their operations.Mark P. Sharfman, Teresa M. Shaft, and Robert P. Anex Jr., “The Road to Cooperative Supply-Chain Environmental Management: Trust and Uncertainty among Pro-active Firms,” Business Strategy and the Environment 18, no. 1 (January 2009): 1–13. Businesses must state clear and reasonable expectations and allow sufficient lead time for suppliers to respond. They must also be willing to listen to suppliers.Business for Social Responsibility Education Fund, Suppliers’ Perspectives on Greening the Supply Chain (San Francisco: Business for Social Responsibility Education Fund, 2001), accessed January 11, 2011, http://www.getf.org/file/toolmanager/O16F15429.pdf. Furthermore, companies cannot simply issue guidelines from their headquarters; their representatives must instead be available on the ground and cooperating with local contacts to ensure results and prevent increased competition within the supply chain.Terry F. Yosie, Greening the Supply Chain in Emerging Markets: Some Lessons from the Field (Oakland, CA: GreenBiz, 2008), accessed January 11, 2011, http://www.greenbiz.com/sites/default/files/document/GreenBiz_Report_Greening _the_Supply_Chain.pdf. Indeed, suppliers need incentives and assurance that their share of the profit will be protected if they innovate to improve the process because maximizing the overall value of the supply chain may reduce value for individual links.Jonathan D. Linton, Robert Klassen, and Vaidyanathan Jayaraman, “Sustainable Supply Chains: An Introduction,” Journal of Operations Management 25, no. 6 (November 2007): 1078. For example, a design for disassembly that relies on pieces that snap together may obviate the need for suppliers of adhesives, even if it may create demand for disassembly and remanufacturing services.

Reverse supply chains complicate the overall supply chain, and therefore they need to be carefully crafted and considered in overall product design, production, and distribution. Materials and components recovered from used products need to reenter the same forward supply chain as new materials or components. Hence companies must recover items efficiently, train employees or subcontractors to assess properly the condition of a recovered item and what is salvageable and what is not, and manage their inventory to even out variation in the rate and quality of returned items.V. Daniel R. Guide Jr., Vaidyanathan Jayaraman, Rajesh Srivastava, and W. C. Benton, “Supply-Chain Management for Recoverable Manufacturing Systems,” Interfaces: International Journal of the Institute for Operations Research and the Management Sciences 30, no. 3 (May/June 2000): 125–42; also Nils Rudi, David F. Pyke, and Per Olav Sporsheim, “Product Recovery at the Norwegian National Insurance Administration,” Interfaces: International Journal of the Institute for Operations Research and the Management Sciences 30, no. 3 (May/June 2000): 166–79. They must also balance the availability of salvaged components or recycled materials with the need for new components or materials, especially as certain proprietary parts become unavailable or production processes change. In cases when consumers may want the same item they had before with only minor changes, such as a vehicle, businesses will also have to track individual pieces through disassembly and refurbishment.V. Daniel R. Guide Jr., Vaidyanathan Jayaraman, Rajesh Srivastava, and W. C. Benton, “Supply-Chain Management for Recoverable Manufacturing Systems,” Interfaces: International Journal of the Institute for Operations Research and the Management Sciences 30, no. 3 (May/June 2000): 125–42.

After establishing a green supply chain, companies need to assess its performance. In their 2008 survey of seventy supply-chain executives, Lassar and Gonzalez noted, “Almost 40 percent of the 56 firms that are active with green activities do not have any metrics to measure green/sustainability results in their firms.”Walfried M. Lassar and Adrian Gonzalez, The State of Green Supply Chain Management: Survey Results (Miami, FL: Ryder Center for Supply Chain Management, Florida International University, 2008), accessed January 11, 2011, http://grci.calpoly.edu/projects/sustaincommworld/pdfs/WP_Florida_Supply_Chain_Mgmt.pdf. Companies with metrics tracked quantities such as fuel use, packaging, and so on. Another study corroborates this trend: what metrics companies do have tend to cluster around eco-efficiency indicators, such as packaging used or miles traveled, likely because those are the easiest to observe, quantify, and associate with specific actions.Vesela Veleva, Maureen Hart, Tim Greiner, and Cathy Crumbley, “Indicators for Measuring Environmental Sustainability,” Benchmarking 10, no. 2 (2003): 107–19. Companies can, however, include broader measures such as customer satisfaction. However, even then a company may fall short. A systems, health-oriented, and green approach to design does not always work. Some view Frito-Lay’s SunChips compostable bag (offered to the market consistent with biodegradable bags being the fastest growing segment in packaging) as having failed due to its loud noise when handled. Since the crinkling of the bags at up to eighty-five decibels is comparable to glass breaking or an engine revving, the company has gone back to the drawing board with this packaging design.

Finally, green supply chains had to overcome institutional inertia and confusion. First, large companies with financial and political resources tended to resist change, especially at the outset, because of the large capital and infrastructural investments in the status quo. Walmart’s green initiative, however, appears to be the turning point that moves other large enterprises toward green supply chains.

Second, in 2009, no official criteria defined a green supply chain. Standards such as ISO 14000 usually focus on a single entity and not the supply chain, while legal requirements often focus on products and ingredients. ISO 14001, the core voluntary set of standards, is used by firms to design an environmental management system that provides internal monitoring and provides practices, procedures, and tools for systematic efforts to improve performance. However, nothing defines how much of the supply chain is required to have ISO 14000 or other certifications to qualify for the green supply chain label. When Home Depot solicited its suppliers for candidates to its Eco Options marketing campaign, one manufacturer praised the plastic handles of its paintbrushes as more environmentally sensitive than wooden handles, while another praised the wooden handles of its paintbrushes as environmentally better than plastic.Clifford Krauss, “At Home Depot, How Green Is That Chainsaw?” New York Times, June 25, 2007, accessed January 11, 2011, http://www.nytimes.com/2007/06/25/business/25depot.html?_r=1.

The lack of standards could promote individual certification programs, such as the cradle-to-cradle certification provided by McDonough Braungart Design Chemistry, LLC, which implies a corresponding green supply chain. This program, however, is private, largely to protect the confidential business information of its clients to ensure their cooperation, and has therefore been criticized for its lack of transparency.Danielle Sacks, “Green Guru William McDonough Must Change, Demand His Biggest Fans,” Fast Company, February 26, 2009, accessed January 11, 2011, http://www.fastcompany.com/blog/danielle-sacks/ad-verse-effect/william -mcdonough-must-change; Diana den Held, “‘Criticism on Cradle to Cradle? Right on Schedule,’ Says Michael Braungart,” Duurzaam Gebouwd (blog), March 20, 2009, accessed October 2, 2009, http://www.duurzaamgebouwd.nl/index.php?pageID=3946&messageID=1936. However, the cradle-to-cradle approach is now being explored in California as a statewide system to encourage safer, less polluting design protocols. In the worst cases, vague standards or opaque processes can lead to charges of “greenwashing,” or exaggerating or fabricating environmental credentials.Melissa Whellams and Chris MacDonald, “What Is Greenwashing, and Why Is It a Problem?” Business Ethics, accessed October 2, 2009, http://www.businessethics.ca/greenwashing. Greenwashing distracts people who are serious about taking care of the environment with counterproductive activities, misinforms the public, and undermines the credibility of more substantial initiatives of others.

Nonetheless, resistance to change and lack of an official definition reflect extrinsic problems rather than problems intrinsic to the mechanics of green supply chains. Such problems are more about marketing than about function. As green supply chains prove themselves through superior performance, they will likely become more studied, better understood and defined, and more widely spread. Good starting points for firms that understand these issues as strategic are to look at the inherent risks of not examining their supply chains and to envision a future market position in which a green, differentiated product and brand will grow revenues.

Green supply chains yield a wide range of benefits. They can reduce a company’s negative environmental or social impact, decrease operating costs, increase customer service and sales, promote innovation, and mitigate regulatory risk. The most immediate benefits of green supply chains are reduced environmental harm and operations costs. For example, Fuji Xerox adopted a cradle-to-cradle philosophy that emphasized supporting document services over a life cycle rather than selling photocopiers and forgetting about them. Fuji Xerox leased equipment and recovered 99 percent of materials from used equipment in Asia in 2006, saving $13 million on new materials, generating an additional $5.4 million in revenue, and reducing raw material consumption by 2,000 tons at its factories in China.Fuji Xerox Australia, “Fuji Xerox Innovation Makes Business and Environmental Sense,” news release, September 25, 2007, accessed January 11, 2011, http://www.fujixerox.com.au/about/media/articles/546. Government institutions could also benefit. For example, Norway’s health-care system saved money by refurbishing more medical equipment.Nils Rudi, David F. Pyke, and Per Olav Sporsheim, “Product Recovery at the Norwegian National Insurance Administration,” Interfaces: International Journal of the Institute for Operations Research and the Management Sciences 30, no. 3 (May/June 2000): 166–79. Decreased costs could even accrue to suppliers.Business for Social Responsibility Education Fund, Suppliers’ Perspectives on Greening the Supply Chain (San Francisco: Business for Social Responsibility Education Fund, 2001), accessed January 11, 2011, http://www.getf.org/file/toolmanager/O16F15429.pdf.

Another benefit from green supply chains was increased innovation, largely because people worked together who had not done so before, or new challenges brought new answers. By collaborating with suppliers and designers to design its cradle-to-cradle system, Fuji Xerox saw the opportunity to make material and component improvements. The decision was made to redesign a spring and a roller, saving the US affiliate approximately $40 million annually.Corporate Societal Responsbility: Knowledge Learning through Sustainable Global Supply Chain Management, p 14, accessed April 2, 2011, http://www.reman.org/pdf/Fuji-Xerox.pdf.

Moreover, green supply chains can lead to improved customer satisfaction and higher sales. Through product recovery programs, Dell increased sales and strengthened its brand reputation for customer satisfaction and corporate citizenship. Dell Asset Recovery Services (ARS) designed a customized solution that quickly recovered 2,300 servers from the Center for Computational Research at the University at Buffalo, SUNY. “That solves two problems for us,” said SUNY’s Tom Furlani. “It helps get rid of the old equipment in a cost-effective way, and it allows us to get new, faster equipment that is under warranty.” In addition to secure destruction of hard drive data, the Dell ARS maintains a zero landfill policy and a zero trash export policy. Unwanted equipment is disassembled into materials that reenter the manufacturing stream.Dell, That’s Refreshing, case study, November 2006, accessed January 11, 2011, http://www.dell.com/downloads/global/services/suny_ars_casestudy.pdf. This step also placed Dell in a more favorable position with the Basel Action Network, an NGO that targeted the company as contributing to e-waste exports to emerging economies.

Finally, green supply chains mitigate regulatory burdens and litigation risk. With the increasing severity of environmental regulations in different regions of the world and the global scale of today’s supply chains for even simple products (e.g., cloth from Latin America, cut and assembled into a shirt in China, and the product itself sold in Europe), green supply chains play a critical role in the operations strategy of multinational organizations. The consequences of not meeting regulations in a particular location can be major. For instance, Chinese suppliers have suffered from scandals over lead paint in toys and toxins in pet food and powdered milk, costing companies money in recalls and prompting calls for tighter regulation. In 2009, drywall produced in China was implicated in emissions of toxic sulfur compounds in homes built in America between 2004 and 2008, causing problems for homeowners, builders, and state regulatory agencies.Michael Corkery, “Chinese Drywall Cited in Building Woes,” Wall Street Journal, January 12, 2009, accessed January 11, 2011, http://online.wsj.com/article/SB123171862994672097.html; Brian Skoloff and Cain Burdeau, Associated Press, “Chinese Drywall Poses Potential Risks,” US News and World Report, April 11, 2009, accessed January 11, 2011, http://www.usnews.com/science/articles/2009/04/11/chinese-drywall-poses-potential-risks?PageNr=1.

Green supply chains have arisen in response to multiple, often interwoven problems: environmental degradation, rising prices for energy and raw materials, and global supply chains that link labor and environmental standards in one country with legal and consumer expectations in another. Green supply chains strive to ensure that value creation, rather than risk and waste, accumulates at each step from design to disposal and recovery. They have gained audience with large and small organizations across cultures, regions, and industries. Managing complex relationships and flows of materials across companies and cultures may pose a key challenge for green supply chains. Nonetheless, those challenges are not insurmountable, and the effort to green a supply chain can provide significant benefits.

In our first case we have the opportunity to track Method, an entrepreneurial consumer products company, through two stages in its early growth. The first case presents the company and its unique sustainability strategy, highlighting both the scope of its efforts and unanticipated challenges that arose. Technical notes are provided for background on health threats from exposure to toxic materials in everyday life. The second Method case provides a 2010 update on the company’s activities and distinctive focus on innovation process. It is preceded by a discussion of toxicity issues intended to highlight Method’s ongoing innovative efforts to differentiate itself as a company that is about supply-chain solutions to the chemical hazards increasingly on the minds of consumers and scientists.

It was spring 2007, and Method cofounder Adam Lowry was deep in thought over enchiladas at Mercedes, a restaurant a block from his company’s office on Commercial Street in San Francisco. He began to sketch ideas on a piece of paper to sort the issues troubling him. As a company known for environmentally healthy household products with designer brand appeal, Method was eager to develop a biodegradable cleaning cloth. Sourcing polylactic acid (PLA) cloth from China had not been in his plans, but every US PLA manufacturer Lowry had talked to told him it was impossible for them to create the dry floor dusting cloth he wanted. There was also a genetic modification issue. US PLA producers did not screen their corn plant feedstock to determine whether it came from genetically modified organisms (GMOs). However, Lowry wondered, weren’t any bio-based and biodegradable materials a better alternative than oil-based polyester, the material used by the competition? Yet certain major retailers were unwilling to stock products that weren’t certifiably GMO-free. It was hard enough to manage a fast-growing new company, but why did some people seem willing to stop progress while they held out for perfection on the environmental front? The naysayers made Lowry think carefully about what it meant to be true to the environmental philosophy that formed the backbone of his business. He had often said that Method’s business was to change the way business was conducted. But where should the company draw the line?Andrea Larson, Method: Entrepreneurial Innovation, Health, Environment, and Sustainable Business Design, UVA-ENT-0099 (Charlottesville: Darden Business Publishing, University of Virginia, March 26, 2007). All quotations and references in this section, unless otherwise noted, come from this case.

As a hot new company that had received widespread publicity for its dedication to environmental values and healthy, clean production, use, and disposal of all its products, Method had set high standards. In a relatively short time, it had created a model for excellence in integrating health and environmental concerns into corporate strategy. From only a germ of an idea in 1999, Method had experienced explosive growth during the intervening years. The company proved that home cleaning products could evolve from toxic substances that had to be locked away from children and hidden in cupboards to nice-smelling, stylishly packaged, biodegradable, benign products that consumers proudly displayed on their countertops. In 2006, Inc. magazine listed Method at number seven of the five hundred fastest and most successfully growing firms in the United States. Method stood out in many ways from the typical entrepreneurial firm.

Leveraging only $300,000 in start-up capital, twentysomethings Adam Lowry and Eric Ryan caused small-scale “creative destruction” across a $17 billion industry in the United States by emphasizing the health, environmental, and emotional aspects of the most mundane of products: household cleaners. The company’s differentiating characteristic? Lowry and Ryan assumed from the start that incorporating ecological and human health concerns into corporate strategy was simply good business. By 2007, Method was growing rapidly and was profitable with forty-five employees and annual revenues of more than $50 million. Its products were available in well-known distribution channels (drugstores, department stores, supermarkets, and other retail outlets) in the United States, Canada, Australia, and the United Kingdom. Customers embraced Method’s products, giving the company live feedback on its website, praising the firm and providing tips for the future. They were a loyal crowd and a signal that the time was right for this kind of business model. They even requested T-shirts featuring the Method brand, and the company responded by offering two different shirts: one that said, “Cleans like a mother” and another that simply said, “Method,” both with the company slogan—”People against dirty”—on the back. A baseball cap was also available.

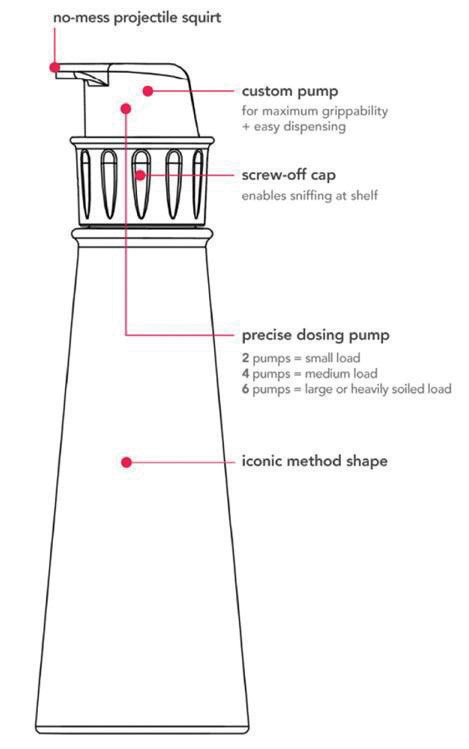

Indeed, “People against dirty” was Method’s stated mission. The company website explains it this way: “Dirty means the toxic chemicals that make up many household products, it means polluting our land with nonrecyclable materials, it means testing products on innocent animals.…These things are dirty and we’re against that.” Under Lowry and Ryan’s leadership, Method shook up the monolithic and staid cleaning-products markets by delivering high-performance products that appealed to consumers from a price, design, health, and ecological perspective—simultaneously. From the original offering of a clear cleaning spray, Method’s product line had expanded by 2007 to a 125-product line of home solutions including dishwashing liquids and hand and body soaps. The “aircare” line, an array of air fresheners housed in innovatively designed dispensers, extended the product offerings in 2006, and the O-mop was added in 2007.

All products were made in alignment with Method’s strategy. They had to be biodegradable; contain no propellants, aerosols, phosphates, or chlorine bleach; and be packaged in minimal and recyclable materials. Method used its product formulation, eye-catching design, and a lean outsourcing network of fifty suppliers to remain nimble and quick to market while building significant brand loyalty.

Method sold its products in the United States through several national and regional groceries, but one of the company’s key relationships was with Target, the nation’s number-two mass retailer in 2007. Through Target’s 1,400 stores in 47 states, Method reached consumers across the United States. International sales were expanding, and the firm was regularly in discussion with new distribution channels.

The US market for soaps and cleaning products did not seem a likely industry for innovation and environmental consciousness. It was dominated by corporate giants, many of which were integral to its founding. Although the soap and cleaning product industry was fragmented around the edges, with a typical supermarket stocking up to forty brands, market share was dominated by companies such as SC Johnson, Procter & Gamble (P&G), Unilever, and Colgate-Palmolive.

To put Method’s position in perspective, its total annual sales were approximately 10 percent of Procter & Gamble’s sales in dish detergent alone ($317.6 million) (2006). P&G’s total annual sales in the category were more than $1 billion. Furthermore, the market for cleaning products was under steady cost pressure from private-label brands, increasing raw materials prices and consumers’ view of these products as commodities. Companies that reported positive numbers in the segment between 2000 and 2006 did so by cutting costs and consolidating operations. Startups such as Seventh Generation and others attempted to penetrate the mass market with “natural” products, but those products were largely relegated to health food stores and chains such as Whole Foods. For Method to have obtained any foothold in this heavily consolidated segment dominated by market giants seemed improbable at best. But for Method founders Lowry and Ryan, the massive scale and cost focus of their competitors offered an opportunity.

“You have all your domestic experiences in that house or wherever you live,” Ryan explained. And so, “from the furniture you buy to your kitchenware, you put a lot of thought and emotion into what you put in that space. Yet the commodity products that you use to maintain this very important space tend to be uninteresting, ugly, and toxic—and you hide them away.”Andrea Larson, Method: Entrepreneurial Innovation, Health, Environment, and Sustainable Business Design, UVA-ENT-0099 (Charlottesville: Darden Business Publishing, University of Virginia, March 26, 2007). Lowry and Ryan didn’t understand why it had to be that way.

They decided to take the opposite approach; if they could create products that were harmless to humans and the natural environment and were attractively designed with interesting colors and aromas, they could disrupt an industry populated with dinosaurs. By differentiating themselves from the competition in a significant and meaningful way, Lowry and Ryan hoped to offer an attractive alternative that also reduced the company’s ecological footprint and had a positive environmental impact. “It’s green clean for the mainstream,” said Lowry, “which wouldn’t happen if it wasn’t cool.”Andrea Larson, Method: Entrepreneurial Innovation, Health, Environment, and Sustainable Business Design, UVA-ENT-0099 (Charlottesville: Darden Business Publishing, University of Virginia, March 26, 2007).

To make green cool, Method took a two-pronged approach. First, it formulated new product mixtures that performed as well as leading brands while minimizing environmental and health impacts. Cleaning product manufacturers had been the target of environmental complaints since the 1950s, when the federal government enacted the Federal Water Pollution Control Act in part to address the foaming of streams due to the use of surfactants, chemicals used in soaps and detergents to increase cleaning power. In addition to surfactants, household cleaners often contained phosphates, chemicals used as water softeners and that also acted as plant nutrients, providing an abundant food source for algae. Fast-growing algae resulted in algal blooms, which depleted oxygen levels and starved aquatic life. Water sources contaminated with phosphates were also toxic for animals to drink. Another environmentally problematic compound in cleaning products was chlorine bleach, which when released into the environment could react with other substances to create toxic compounds. According to the Method website, “A major problem with most household cleaners is that they biodegrade slowly, leading to an accumulation of toxins in the environment. The higher the concentration of toxins, the more dangerous they are to humans, animals, and plant life. The key is to create products that biodegrade into their natural components quickly and safely.”Andrea Larson, Method: Entrepreneurial Innovation, Health, Environment, and Sustainable Business Design, UVA-ENT-0099 (Charlottesville: Darden Business Publishing, University of Virginia, March 26, 2007).

With a degree in chemical engineering from Stanford University, experience researching “green” plastics, and a stint at a climate-change think tank, Lowry saw these issues as opportunities.

Method counted on the competition’s seeing environmental and health issues as “problems.” Doing so allowed Method to seize competitive advantage through designing out human health threats and ecological impacts from the start, while their larger competitors struggled to deal with increasing legislative and public image pressures. Method products sold at a slight premium to compensate for the extra effort. “I knew as a chemical engineer that there was no reason we couldn’t design products that were nontoxic and used natural ingredients,” Lowry said. “It would be more expensive to do it that way. But that was okay as long as we created a brand that had a ‘premiumness’ about it, where our margins would support our extra investments in product development and high-quality ingredients.”Andrea Larson, Method: Entrepreneurial Innovation, Health, Environment, and Sustainable Business Design, UVA-ENT-0099 (Charlottesville: Darden Business Publishing, University of Virginia, March 26, 2007).

The second prong of Method’s attack on the entrenched cleaning products industry was to utilize design and brand to appeal to consumers tired of the same old products. In an industry rife with destructive price competition, Method realized it would have to be different. The founders believed that their competition was so focused on price that “they weren’t able to invest in fragrance or interesting packaging or design.” Lowry explained, “Our idea was to turn that reality on its head and come up with products that absolutely could connect with the emotion of the home. We wanted to make these products more like ‘home accessories.’ We believed there was an opportunity to really reinvent, and in the end, change the competitive landscape.”Andrea Larson, Method: Entrepreneurial Innovation, Health, Environment, and Sustainable Business Design, UVA-ENT-0099 (Charlottesville: Darden Business Publishing, University of Virginia, March 26, 2007).

By focusing their marketing and packaging as the solution “against dirty,” they tapped into consumers’ disquiet with the ingredients in their household cleaners. Through packaging that stood out from the rest, they created the opportunity to deliver the environmental and health message of the products’ ingredients.

Design of packaging to deliver that message was integral to Method’s success from its first sale. Method’s home-brewed cleaning formulas for kitchen, shower, bath, and glass surfaces were originally packaged in clear bottles that stood out on a shelf. “The manager of the store just liked the way the packaging looked,” said David Bennett, the co-owner of Mollie Stones, a San Francisco Bay–area grocer that was Method’s first retail customer. “It looked like an upscale product that would meet our consumer demands, so we went with it.”Andrea Larson, Method: Entrepreneurial Innovation, Health, Environment, and Sustainable Business Design, UVA-ENT-0099 (Charlottesville: Darden Business Publishing, University of Virginia, March 26, 2007).

As design continued to be a key element of Method’s appeal, the company recruited Karim Rashid, a renowned industrial designer who had worked with Prada and Armani. Rashid was responsible for bringing a heightened sense of style to Method’s packaging while continuing to focus on environmental impact. This led to the use of easily recycled number one and number two plastics (the types of plastic most commonly accepted by municipal recycling centers). Method’s approach seemed to represent a younger generation’s more holistic mental model. This small firm seemed to provide a window into a future where health, environmental, and what were increasingly called “sustainability issues” would be assumed as part of business strategy and product design.

PLA was an innovative and relatively new plastic material derived from plants such as corn, rice, beets, and other starch-based agricultural crops. PLA biodegraded at the high temperatures and humidity levels found in most composting processes. NatureWorks was the first large-scale plant in the United States to produce PLA in resin (pellet) form, based on milled material made from farm-supplied corn and corn waste. The resin pellets went to a fiber manufacturer who made bales; those bales of PLA material went next to the nonwoven cloth manufacturer, which converted it into giant rolls of nonwoven cloth. Next, a converter took the bulk nonwoven cloth, cut it into shapes, and packaged it according to the specifications of a customer such as Method. When NatureWorks first began operations, demand was limited. That picture changed quickly between 2004 and 2006, and by 2007 the plant could not produce its PLA feedstock resins fast enough to meet worldwide demand. PLA came out of the facility in pellet form and was melted, extruded, spun, and otherwise manipulated by converters at different steps of the supply chain into a virtually endless spectrum of materials for different applications across a wide range of product categories.

As a replacement for ubiquitous oil-based plastic feedstock, PLA promised a departure from the petroleum-based plastic materials that had come to dominate since synthetic plastics were first developed in volume after World War II. PLA had proved itself a particularly high-performing and cost-effective raw material that was well suited as a substitute for polyethylene terephthalate (PET) in many applications. PET was the oil-based polymer known generically as polyester and used extensively in packaging, films, and fibers for textiles and clothing.

The competition’s wipes and mop heads were made of petroleum-based nonbiodegradable plastic material, typically polyester or polypropylene. Although microfiber was quickly becoming commonplace, microfiber and the denier unit of measurement were first associated with material in women’s hosiery. Technology advances permitted polyester microfiber production for very fine fiber applications, and just as microfiber had become common in clothing lines, it was also used as a more effective wiping and cleaning product. Microfiber was fiber with strands measured at less than one denier, a unit of weight used to describe extremely fine filaments and equal to a yarn weighing one gram per nine thousand meters. Whether made from corn or oil, microfiber material, used by most companies selling residential cleaning wipes by 2006, made an excellent cleaning cloth. Its structure enabled the fiber surface to more effectively pick up dirt and dust compared with conventional materials and methods. The microfiber wipes could be washed and reused, providing greater durability than alternative products that were typically thrown away immediately after use.

Consistent with Method’s environmental and sustainability philosophy, Lowry wanted to use bio-based materials, specifically PLA nonwoven cloth, for the dry floor dusting product. Ultimately he wanted PLA to be the basis for all fibers used, both nonwoven disposable cloth and reusable woven microfiber. If customers weren’t grabbed by the marketing message that the mop was sexy and hip (a message consistent with Method’s playful tone), they might be pulled in by the ergonomic O-mop’s more effective, biotech-based, and nontoxic floor cleaning.

Lowry knew most disposable wipes ended up in landfills, not compost piles, even with their extended life. So the company supported municipal recycling and composting infrastructure development in an effort to encourage cradle-to-cradleCradle-to-cradle was an increasingly popular term that referred to a product cycle in which materials could be manufactured, used, then broken down and used again with no loss of quality; for more information on this concept, see William McDonough and Michael Braungart, Cradle to Cradle: Remaking the Way We Make Things (New York: North Point Press, 2002). resource use, or at least raise awareness and encourage behavior in that direction. Method estimated that eighty-three thousand tons of “wipe” material made of polyester or polypropylene plastic was ending up in landfills annually, enough to fill nine thousand tractor-trailers. If using PLA could reduce oil feedstock use even a little, he reasoned, it was an improvement. Even if the PLA fiber went to landfills, where temperature and humidity never reached the ideal composting levels that would quickly and thoroughly break it down, it would still decompose safely, perhaps after one to two months, unlike oil-based fibers, which could remain in landfill disposal sites in the same condition for thousands of years.

The market for bio-based plastic materials had taken off by 2007, but Lowry had had no luck finding a US manufacturer to create a PLA-based fabric suitable for the white, nonwoven, dry-floor duster cloth used with the O-mop. He had just talked with the last on his list of PLA manufacturers, and the answer was no. They had all told him it couldn’t be done. The material was too brittle, they couldn’t process it, it wouldn’t run on their machines, and the strands were too weak. In short, PLA nonwoven cloth for this application was technologically impossible.

Lowry picked up the phone and placed a call to a company he knew in China—a departure from business as usual given that 90 percent of Method’s inputs were sourced in the United States. Chinese suppliers often were excellent, but domestic sourcing was preferable to avoid the high transportation costs of moving product long distances. Typically the farther the transport requirement, the greater the fossil fuel use, so the choice seemed inconsistent with the firm’s sustainability approach. But Lowry was sure the dry-floor dusting cloth could be made with PLA resins, and the Chinese manufacturer confirmed it. Lowry placed the order. A Taiwanese fiber manufacturer would make the bales and send them to the Chinese nonwoven cloth manufacturer that would pass on the cloth to a nearby converter that would in turn cut and package it to meet Method’s needs. Lowry knew the suppliers were good and reliable and that the product would arrive promptly. Perhaps all Method’s PLA products would need to come from China. But was sourcing from the other side of the world “sustainable” in the sense that he and Ryan tried to apply sustainability principles to the company’s operations?

The other issue on Lowry’s mind was that Method’s products could be deemed unacceptable in certain distribution channels that would not tolerate any GMOs in their products. PLA was produced from agricultural material (often corn or cornfield waste material) that was brought by farmers to a centrally located milling plant that converted it and separated out the components from which PLA was made. There was no monitoring of the corn coming into the milling facility; thus there was no guarantee that all inputs to the PLA resin-producing process were free of GMOs. If Lowry used PLA, it meant certain large and reputable buyers would refuse to put Method products on their shelves. Even so, to Lowry, it seemed preferable to substitute PLA for petroleum-derived products and compromise on the GMO issue for the time being. After a particularly discouraging conversation with a company that declined to do business with Method until it agreed to stop using GMO agricultural inputs, he decided to write out his thoughts in an essay, both to sort them out for himself and to draft a position paper that he could later post on the Method website.

As our knowledge base grows regarding exposure to toxins, we become more informed and better equipped to find solutions. We are capable of learning and absorbing feedback from the environment and our bodies. Lead was removed from gasoline in the United States and extensive efforts made to remove lead-based paint from older homes, thereby significantly reducing exposure to lead (a neurotoxin), particularly for children. Chlorofluorocarbons (CFCs), known to break down upper atmosphere ozone, were banned enabling recovery of the ozone layer and over time reducing the ozone hole that formed every year over parts of the Southern Hemisphere. As a species, we act, we receive feedback, we adjust and adapt. We are beginning to learn and adapt with respect to toxic chemicals exposure. However, materials toxicity and contamination is just starting to receive attention and still remains secondary in the media’s attention due to the current focus on climate and energy issues (topics that also require attention to materials and toxic inputs/outputs). Nevertheless, materials issues will be acknowledged and addressed. The pattern will be similar to other arenas that challenge human ingenuity: most people will be overwhelmed by the problem scale, while others, the entrepreneurial individuals (and ventures they create), will drive innovation to create benign alternatives.See http://www.warnerbabcock.com for an example of a company committed to change

The next two sections provide additional background information on toxic substances. They are followed by a second case on Method that demonstrates how forward-thinking companies work on an ongoing basis to eliminate questionable chemical compounds from their products through innovative processes that lead to breakthrough designs and safer products in the marketplace.

In the early 1960s, US scientist and writer Rachel Carson spoke about the risks of toxic chemicals: “We are subjecting whole populations to exposure to chemicals which animal experiments have proved to be extremely poisonous and in many cases cumulative in their effect. These exposures now begin at or before birth and—unless we change our methods—continue through the lifetime of those now living. No one knows what the results will be, because we have no previous experience to guide us.”Rachel Carson, Silent Spring (New York: Houghton Mifflin, 1962).

We have made progress in the face of the abundant evidence that increases in cancer and other disease rates are the result of exposure to chemicals. The US Environmental Protection Agency (EPA) was established in 1970 partly in response to Carson and others who foresaw the dangers of society’s ill-informed experimentation with toxic chemicals. Similar agencies now exist in most countries and the United Nations. Environmental and health nongovernmental organizations (NGOs) have become powerful change agents. Federal and state laws and international agreements have been passed banning or severely restricting the manufacture and use of certain exceptionally dangerous and persistent chemicals. However, progress is slow and public awareness insufficient. We remain vulnerable to both existing chemicals and hundreds of new ones that are invented and introduced into commerce daily.Andrea Larson, Darden Business School technical note, Toxic Chemicals: Responding to Challenges and Opportunities, UVA-ENT-0043 (Charlottesville: Darden Business Publishing, University of Virginia, 2004). Information presented in this section comes from this study.

More than thirty years after Carson’s book Silent Spring was published, scientists Theo Colborn and John Peterson Myers and a coauthor renewed the warning about widespread molecular toxins in the book Our Stolen Future (1996):

The 20th century marks a true watershed in the relationship between humans and the earth. The unprecedented and awesome power of science and technology, combined with the sheer number of people living on the planet, has transformed the scale of our impact from local and regional to global. With that transformation, we have been altering the fundamental systems that support life. These alterations amount to a great global experiment—with humanity and all life on earth as the unwitting subjects. Synthetic chemicals have been a major force in these alterations. Through the creation and release of billions of pounds of man-made chemicals over the past half-century, we have been making broad-scale changes to the earth’s atmosphere and even in the chemistry of our own bodies.…The global scale of the experiment makes it extremely difficult to assess the effects. Over the past fifty years, synthetic chemicals have become so pervasive in the environment and in our bodies that it is no longer possible to define a normal, unaltered human physiology. There is no clean, uncontaminated place, nor any human being who hasn’t acquired a considerable load of persistent hormone-disrupting chemicals. In this experiment, we are all guinea pigs and, to make matters worse, we have no controls to help us understand what these chemicals are doing.Theo Colborn, Dianne Dumanoski, and John Peterson Myers, Our Stolen Future (New York: Penguin Group, 1996), 239–40.

Synthetic chemicals are everywhere—in the plastics used in packaging, cars, toys, clothing, and electronics and in glues, coatings, fertilizers, lubricants, fuels, and pesticides. We make or “synthesize” chemicals from elements present in nature. Many “organic”“Organic” chemicals are chemicals that have a carbon backbone. Some occur naturally and some are synthetic. There is no connection between the term organic as it is used in chemistry and the use of the word in phrases such as organic food or organic farming. or carbon-based chemicals are derived from petroleum. We use synthetics to serve many purposes that natural materials cannot serve as well, and industry and consumers often save money in the process. Without synthetics, we wouldn’t have computers, television, and most drugs and medical equipment. Synthetic chemicals, however, have dangers as well as benefits. Those dangers are often unknown or even unsuspected when a chemical is first introduced. They may become evident only after thousands or even millions of pounds of that chemical have been released into the environment through industrial and agricultural processes and energy generation, or as products, emissions, or other wastes.

Synthetic chemicals’ detrimental environmental and health consequences are unintentional. The pesticide dichloro-diphenyl-trichloroethane (DDT), for example, was never intended to kill bald eagles or robins.Rachel Carson, Silent Spring (New York: Houghton Mifflin, 1962), 118–22. The chlorine bleaching process used in paper mills wasn’t meant to disrupt the endocrine systems of fish downstream.Ann Platt McGinn, Why Poison Ourselves? A Precautionary Approach to Synthetic Chemicals, Worldwatch Paper #153 (Washington, DC: Worldwatch Institute, November 2000), 22. Polychlorinated biphenols (PCBs) and pesticide residues weren’t supposed to end up in human breast milk, nor were they supposed to affect the immune and endocrine systems or possibly cause sperm decline and even infertility in men.Theo Colborn, Dianne Dumanoski, and John Peterson Myers, Our Stolen Future (New York: Penguin Group, 1996), 178.

Synthetic chemicals were first produced in laboratories during the nineteenth century. DDT was invented in 1874 in Germany and began its infamous career as pesticide in the 1930s. Before World War II, pesticides consisted mainly of metals such as arsenic, copper, lead, manganese, and zinc and compounds found in plants such as rotenone, nicotine sulfate, and pyrethrum. Plastics from cellulose were first created in the 1890s. Beginning in about 1900, synthetic plastics produced from oil began to find their way into industry. Polyvinyl chloride (a.k.a. “vinyl” or PVC) was discovered in the 1920s. PCBs were introduced in the 1920s. Steady progress through the early twentieth century led to rapid breakthroughs during the World War II years and the creation of thousands of new chemicals every year since. Some toxic chemicals are not created intentionally. Dioxins, for example, are by-products from chlorine-product manufacturing, combustion (especially of plastics), and paper bleaching.Ann Platt McGinn, Why Poison Ourselves? A Precautionary Approach to Synthetic Chemicals, Worldwatch Paper #153 (Washington, DC: Worldwatch Institute, November 2000), 9.

For most people, it would be hard to deny the benefits of the chemical era. Pharmaceuticals, plastics, semiconductors, disinfectants, and food preservatives are just a few of the many synthetic chemical–based conveniences on which we have come to depend. However, rather like the famous story of the sorcerer’s apprentice, the junior-level alchemist who knows enough to unleash the forces of magic but not enough to control them, we have the capacity to create a vast array of products with synthetic chemicals but are politically and technologically constrained in our ability to cope with the pollution and wastes we create along the way.

The chemists, physicists, engineers, and corporations who brought us the “green revolution” in agriculture, plastics, fuel for our vehicles, microchips, and myriad other useful products have also given us many unintended consequences. Even if you eat organic foods, prefer natural wood and leather furniture, and wear only organic cotton and wool clothing, the house you live in, the car you drive, and nearly everything else that you consume is dependent on synthetic chemicals at some point in its life cycle.

Hazards associated with toxic ingredients in pesticides, solvents, lubricants, plastics, fuels, exhaust gases, cleaning fluids, and hundreds of other consumer and industrial substances are generally thought of in terms of impacts on human health, wildlife, and ecosystems. Human health impacts from toxic synthetic chemicals range from minor skin irritations and sinus conditions to chronic asthma, severe nervous system disorders, respiratory illnesses, cancers, and immune system dysfunction. Table 6.1 "Chemical Carcinogens in the Workplace" shows some classes of chemicals known to cause cancer in the workplace.Peter H. Raven and George B. Johnson, Biology, 5th ed. (New York: McGraw Hill, 1999), 342, table 17.3.

Table 6.1 Chemical Carcinogens in the Workplace

| Chemical | Cancer | Workers at Risk for Exposure | |

|---|---|---|---|

| Common Exposure | Benzene | Myelogenous leukemia | Painters, dye users, furniture finishers |

| Diesel exhaust | Lung | Railroad and bus-garage workers | |

| Mineral oils | Skin | Metal machining | |

| Pesticides | Lung | Sprayers | |

| Cigarette tar | Lung | Smokers | |

| Uncommon Exposure | Asbestos | Mesothelioma, lung | Brake-lining and insulation workers |

| Synthetic mineral fibers | Lung | Wall and pipe insulation installers; duct-wrapping workers | |

| Hair dyes | Bladder | Hairdressers and barbers | |

| Paint | Lung | Painters | |

| PCBs | Liver, skin | Hydraulic fluids and lubricants workers | |

| Soot | Skin | Chimney sweeps, bricklayers, firefighters | |

| Rare Exposure | Arsenic | Lung, skin | Insecticide/herbicide sprayers; tanners; oil refiners |

| Formaldehyde | Nose | Hospital and lab workers; wood, paper mill workers |

Source: Andrea Larson, Darden Business School technical note, Toxic Chemicals: Responding to Challenges and Opportunities, UVA-ENT-0043 (Charlottesville: Darden Business Publishing, University of Virginia, 2004).

Wildlife and ecosystems are often impaired by toxic chemical exposure long before we are aware that any damage has been done. In the mid-1980s, scientists found that the alligators in central Florida’s Lake Apopka were born with faulty reproductive systems following an accidental spill from the Tower Chemical Company more than ten years earlier. In 1998, farmland near the lake was allowed to flood as part of a wetland restoration project. Years of pesticide-intensive farming had taken its toll. Vast numbers of fish-eating birds such as herons and egrets died in as toxic chemicals from flooded agricultural fields moved up the food chain from algae and small aquatic animals to the amphibians and fish species the birds ate. By the time the birds consumed the chemicals, they had bioaccumulated to concentrations that caused acute poisoning.Ted Williams, “Lessons from Lake Apopka,” Audubon, July–August 1999, 64–72.

Polar bears also are suffering from bioaccumulationThe concentration of a substance in living organisms that are exposed by breathing air, eating plants that have taken up the chemical from the soil, or drinking water that is contaminated with the substance. of toxins, but their pollutants come from thousands of miles away, carried by ocean and air currents. The toxins are concentrated through the food chain until prey species such as seals have millions of times the amount of heavy metal or persistent organic chemical that is found in the water.Theo Colborn, Dianne Dumanoski, and John Peterson Myers, Our Stolen Future (New York: Penguin Group, 1996), 88–91.